A breakthrough in insulating glass technology

LiteZone® insulating glass

R17 performance

Lowest life cycle cost

60 year lifespan

LiteZone® is a next-generation, award-winning, ultra-energy-efficient insulating glass unit that makes possible the world’s most energy-efficient and longest-lasting windows.

Ultimate Energy Efficiency

They reduce energy use, allow for lower HVAC capacity, and support thinner wall construction. LiteZone® windows have insulation values up to R18.9 (U=0.0529) for full systems and R21.7 (U=0.0461) at the glass center, based on

NFRC standards.

Extreme Longevity

LiteZone® glass units have a lifespan of over 60 years—about 3X longer than typical triple-pane units. They use air instead of gas fill to avoid performance loss, are pressure-equalized to reduce stress, and have an impermeable edge seal and strong spacer connections for durability.

Excellent Sound Insulation

Windows using LiteZone® can achieve sound insulation that is comparable to an 8" thick concrete block wall, with a minimum Sound Transmission Class (STC) of 40. Acts as well as acoustic windows, but at a lower cost.

Superior Human Comfort

The inside surface temperatures of windows using LiteZone® will remain near room temperature to help ensure living spaces are always comfortable, regardless of how hot or cold it is outside, while also eliminating condensation.

Maximum Design Flexibility

LiteZone® provides design flexibility to allow generous glass areas with unimpeded views as large as 6' x 10', which weigh less than triple-pane glass units. Allows the use of large windows to reduce the amount of thermally inefficienct frames.

Lowest Life Cycle Costs

Life cycle costs that are 40% to 70% less than triple pane IGUs, depending on the LiteZone® glass unit used. Life cycle costs include the energy savings and the cost to replace IGUs during the estimated 60-year life of a building.

HOW IT WORKS

Designed for Long Life

LiteZone® overcomes the limitations of conventional IGUs to deliver a 60-year lifespan—on par with the life of a building. It uses only air (not argon or krypton), avoiding declining performance or decompression problems as argon or krypton escape from the glass unit over its life.

Durable materials with similar thermal expansion rates and a pressure equalized design, minimizes stress and ensures a long life.

A strong, insulating fiberglass spacer and flexible structural connections to the glass lites that are 4x stronger than in typical IGUs. A stainless steel foil wrap blocks water vapor transimission through the edge seal, film suspension system applies virtually no stress to the film, making LiteZone® a structurally sound, ultra-long-lasting IGU solution.

Scalability

LiteZone® glass units offer insulating values from R3.1 to R22.7 (centre of glass), depending on configuration.

Performance is adjusted by changing the number of films (1–8), type and number of low-e coatings, gap sizes, and overall unit thickness (1.5” to 7.6”). Different fiberglass spacers support this modular design.

Insulation Zone

The thickness of LiteZone® glass units enables use with window frames that have significantly wider thermal breaks, creating an “insulation zone” necessary to achieve overall window R-values between R12 and R19 or higher.

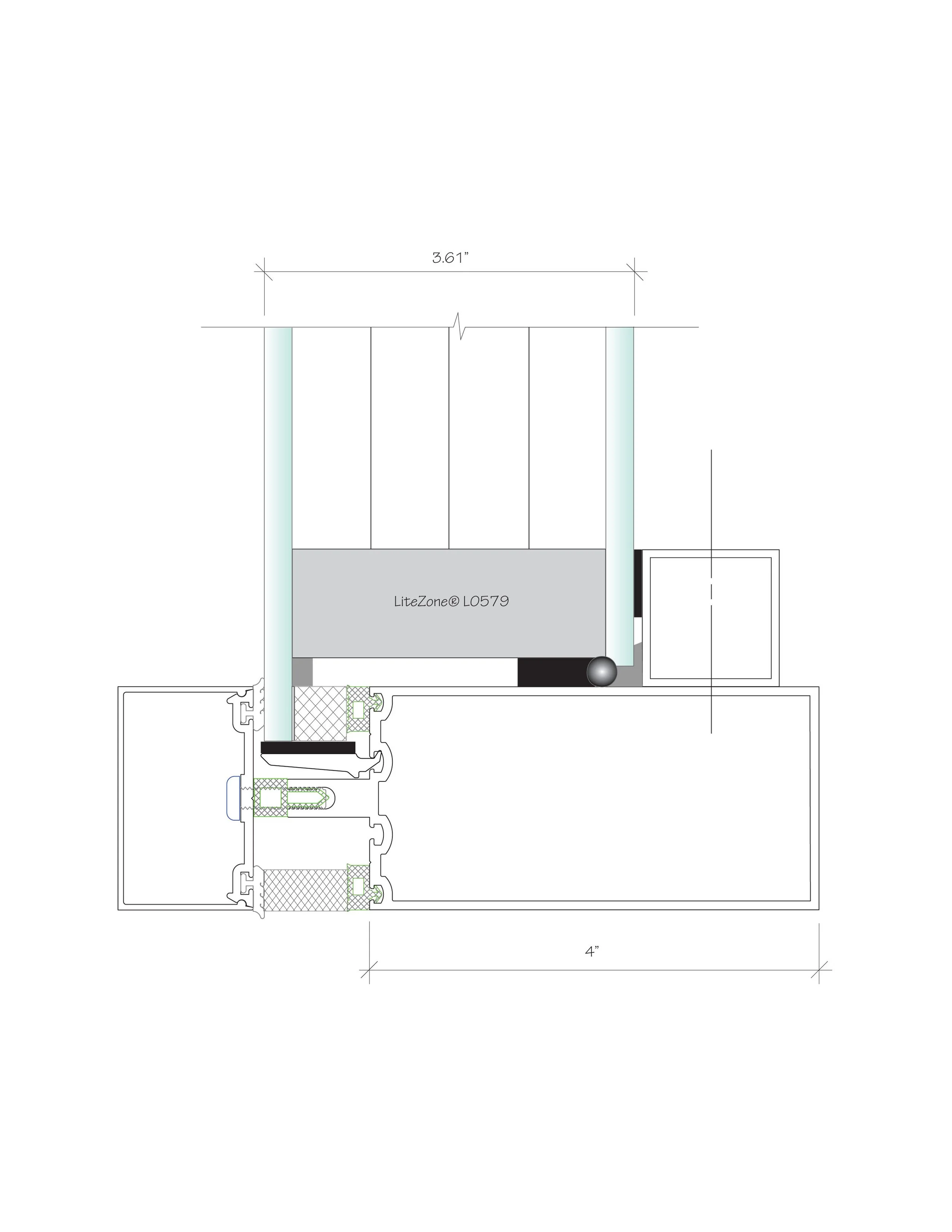

Conventional 1–2 inch thick glass units limit performance because frame insulation is constrained by the narrow thermal break. Since thermal resistance depends on material thickness, a thicker glass unit—such as the 4.4 inch LiteZone® L0679—allows the frame to reach up to R9 at the edge, greatly improving total window performance.

Minimizing Weight

LiteZone® glass units use up to 8 lightweight PET film layers to achieve high insulating performance with minimal added weight and at lower cost.

Compared to similarly sized triple-pane IGUs, LiteZone® units are significantly lighter: a 5’ x 8’ L0479 unit (2 films) weighs about 40% less while offering 25% higher insulation, the L0679 (4 films) weighs 35% less with 80% higher insulation, and the L1079 (8 films) weighs 22% less with 250% higher insulation.

Construction

LiteZone® glass units feature exterior and interior glass lites with optional low-e coatings, and between 1 and 8 air-filled, pressure-equalized cavities containing PET film layers.

The number of films and use of low-e coatings vary based on required performance. A proprietary fiberglass spacer adjusts in width to accommodate additional films, supported by a proprietary film suspension system and pressure equalization conduit with desiccant. The perimeter is sealed with a stainless steel vapor barrier, and both front and back seals use structural silicone, stainless steel foil, and polyisobutylene. Very High Bond (VHB) structural tape is used to attach the glass to the spacer.

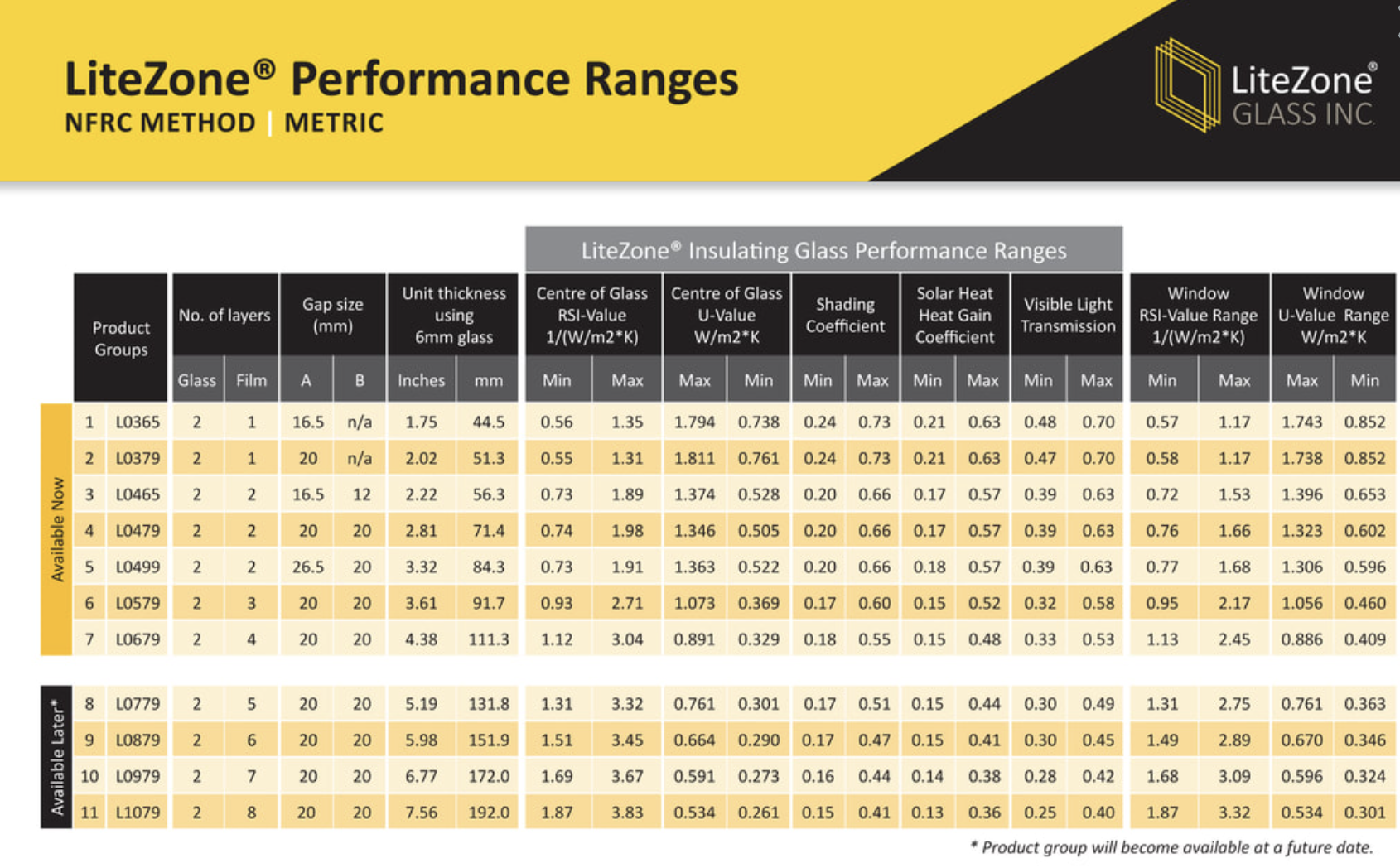

PERFORMANCE

-

The highest performing product group is L1079 which can achieve R21.7 (RSI3.83) centre of glass and an R18.9 (RSI3.32) window.

Each of the 11 LiteZone® product groups is distinguished by the number of suspended PET films layers (1 to 8 films), the size of the gaps between each layer and the overall glass unit thickness (1.75” to 7.56” thick (using 6 mm glass lites). Performance within each product group then varies depending on the number and type of low-e coats used.

-

LiteZone® insulating glass units range in thickness from 1.75" to 7.6", depending on the configuration and desired performance. In today's residential construction typical overall wall thickness is about 7" including exterior finishes.

A 7" thick wall can accommodate window frames carrying glass units up to about 4.5" thick. A 7" wall can achieve an insulating value of about R19. A LiteZone® thick IGU can achieve an R12 window with ~R15 centre of glass, complementing the wall R-value much better than previously possible.

Some high performance walls have overall wall thicknesses as much as 10" to 13" including exterior finishes. By adding insulation to the exterior, these kind of walls can achieve insulating values in the range of R40 to R60 (see adjacent photos).

A 10" to 13" wall can accommodate window frames carrying the thickest LiteZone® glass units. A LiteZone® 7.6" thick IGU can achieve an R19 window with ~R22 centre of glass.

It makes sense for energy efficient homes to take advantage of their wall thickness to install windows with highly energy efficient thicker LiteZone® glass, in order to complement the wall R-value.Consider that large glass units are more economical and energy efficient than small glass units, because they have less energy inefficient and costly edge area in proportion to their centre of glass area. Therefore LiteZone®, with up to ~R20 centre of glass, makes it possible for highly energy efficient buildings, even with R40 to R60 walls, to have large windows and more glass area and still meet their energy efficient design objectives and budgets.

LiteZone® achieves the highest window insulating values.

TESTING

-

LiteZone's® values have been derived using Window 6.3 and Therm 6.3 simulation software from Lawrence Berkeley National Laboratory, Berkeley, CA, and are based on NFRC 100-2010 weather conditions for a 1.2 m x 1.5 m (~4 ft. x ~ 5ft.) window.

The derived insulating value for a wood framed fixed window using a LiteZone® insulating glass unit has been confirmed by a test performed by Intertek Testing Services Ltd. for thermal performance in accordance with ASTM C1199-14 (Standard Test Method for Measuring the Steady-State Thermal Transmittance of Fenestration Systems Using Hot Box Methods).

Intertek concluded that, "The Overall Thermal Transmittance of the sample was found to be 0.081 Btu/hr*ft2*°F (0.48 W/m2*K)." The derived U-value of 0.076 (R13.16) using Window 6.3 and Therm 6.3 is within the 6.3% margin of error of the test result's U-value of 0.081 (R12.35). -

The durability of LiteZone® L0499 insulating glass units has been confirmed by a test performed by Element Materials Technology Canada Inc. in accordance with ASTM-E2190-10 (Standard Specification for Insulating Glass Unit Performance and Evaluation) as modified to accommodate the pressure equalization feature and the extra thickness of the LiteZone® IGUs. The details of the modifications to the test procedures are described in the adjacent Test Report.

The modifications in the test procedures were necessary because the ASTM-E2190 test standard has been developed for the standard thickness of conventional IGUs and for IGUs which are not pressure equalized. The primary objective of this test is to determine the durability of the glass unit edge seal and to determine the risk of a chemical fog forming within the IGU due to the potential chemical volatility of the materials used in the manufacturing of the IGUs. This test objective was accomplished by the test procedures performed on the LiteZone® glass units. -

An in-house test was commenced in March 2018 to demonstrate that the LiteZone® edge seal is impermeable to water vapour. A small LiteZone® L0499 insulating glass unit ("Test Unit") was manufactured without a breather tube for the pressure equalization system. The Test Unit was placed in a bucket of water, submerging both edge seals in water. Water in the bucket that evaporated was replaced to keep the Test Unit submerged continuously.

Periodically the Test Unit was removed from the bucket of water and the internal frost point was determined using the same dry ice frost point testing device and procedures as specified in ASTM-E2190.

After being submerged continuously for about 2.5 years, on September 28th, 2020 the Test Unit was removed from the bucket of water and a test to determine its internal frost point was performed. The coldest temperature that the dry ice frost point testing device could reach was -66 C and at that temperature no frost could be observed within the Test Unit.

The September 28th, 2020 frost point test shows that the Test Unit's edge seal has not allowed any measurable quantity of water to pass into the internal space of the Test Unit after 2.5 years of being continuously submerged in water. No other IGU we are aware of could survive this test (i.e. without becoming fogged).

Click on the charts to expand

LiteZone Glass Inc. manufactures insulating glass units (IGUs), not windows or curtain walls. We will be happy to assist you with selecting the best LiteZone® insulating glass for your needs and will make recommendations for the various framing system options best suited for your project.

PROJECT EXAMPLES

Replacement of IGUs in high-rises

Upgrade old or failed IGUs for improved comfort and

reduced energy costs.

Fogged insulating glass units in window systems requiring IGUs that are 3.3" thick. LiteZone Glass Inc. supplied and installed LiteZone® L0499 insulating glass units into the existing window frames without the need for modifications. The optical properties of the new LiteZone® IGUs were made the same as the properties of the original IGUs being replaced.

Curtain Walls for New Builds

Use LiteZone® IGUs to utilize large expanses of glass.

The use of LiteZone® enables the developer to use large expanses of glass in new build for maximum views and daylight, while ensuring a high level of occupant comfort, while complying with the building energy code in Ontario, and while still being able to use a geothermal field for both heating and cooling the building. The cost savings in the heating and cooling systems made possible by LiteZone® largely offset the premium price for LiteZone®.

Curtain Wall Retrofits

Use thicker, higher performing LiteZone® IGUs to upgrade existing curtain walls designed for a 1” thick IGU.

Higher performing thicker LiteZone® glass units can be installed in existing curtain wall systems without modifications. A spacer is used to fill the 1” glass pocket against the offset exterior glass pane. An aluminum tube is used as an interior glass stop. A heal bead of silicone is used on the interior glass to establish an interior air seal.